How are sustainable fabrics made?

However, the focus of the EU waste management policy is placed on the disposal of waste, the recovery of energy, recycling, reusing and preventing waste. And so is ours!

What does sustainability actually mean?

Our common Future:

“Sustainable development meets the needs of the present without compromising the ability of future generations to meet their own needs.”

Forum for the future:

“Sustainable development is a dynamic process which enables people to realize their potential and improve their quality of life in ways which simultaneously protect and enhance the earth’s life support systems.”

When talking about sustainability, we have to consider the environmental impact as well as the social impact.

Environmental impact

Environmental impact can be caused by using water, land, chemical and energy. CO2 emission or landfill are also important. These threats to the environment can be caused during the raw material extraction, during processing, during the use-phase when washing the fabric and also when throwing it “away” after using it.

Social impact

These days, most of the fabric and garment production takes place in Asia. The salaries of the workers abroad are much lower than in Western countries such as in the Netherlands.

Not only are the transportation distances very long – the working conditions are also often very poor, sometimes even dangerous.

The social topic is often left out when talking about sustainability. But, can we really talk about sustainable fabrics, when the people who are producing them are not treated right?

The choice of raw material

When making a sustainable fabric, the choice of raw material is obviously of great importance. We can differentiate between synthetic fibres, natural fibres and man-made fibres. Natural fibres can be of vegetal or animal origin. Even though synthetic fibres have a bad reputation these days, they are not always worse in terms of sustainability.

Sustainability – quality – transparency

Different fibres come with different properties. This is important to know, because sustainability is closely related to quality. When creating a sports T-shirt for an athlete for example, you would desire to obtain cooling, lightweight & fast drying properties of the fabric. These characteristics are easy to obtain when shaping synthetic fibres.

Natural fibres however would be the wrong choice. When talking about sustainability, the application of the fabric is very important. Once the fabric can fulfil its purpose due to the right properties, the consumer will be satisfied and the fabrics “life” extended and worthy.

Processing

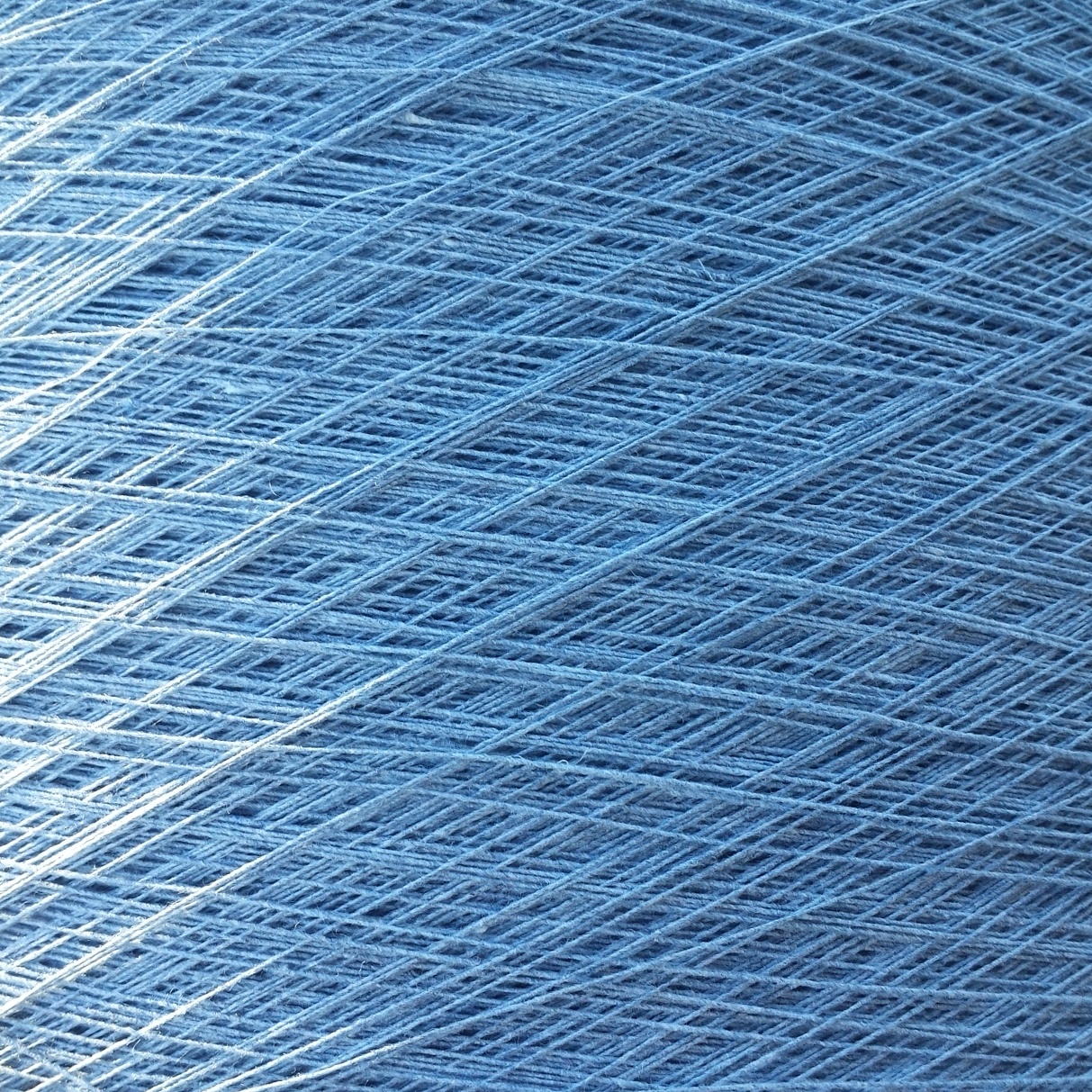

In order to make a fabric from the raw material, the fibres have to get spun into a yarn. The yarn usually undergoes an aftertreatment, called sizing, to increase strength and tear resistance. Then the yarn gets woven or knitted into a cloth. The cloth then undergoes some finishing processes.

Finishing

Finishing includes bleaching and dyeing. There are also many more finishing processes to enhance the feel, the drape or the lustre of a fabric. In general, the finishing process adds up to the environmental impact during the production process of the fabric. Depending on the later application these finishing steps might be desired and necessary.

Bleaching is especially harmful to the environment. Strong and toxic chemicals are used during bleaching. When aiming on a sustainable fabric production, this step should be avoided. At Enschede Textielstad, we neither have to bleach our fabrics, nor do we dye them. All the colours of our fabrics are obtained by the recycled yarns we use.

How to compare the sustainability of fabrics to each other?

There are various tools available to assess the impact of a fabric based on different impact categories. As described in the international standard ISO 14040:2006, a Life cycle analysis (LCA) aims to reveal potential environmental aspects and impacts throughout a product’s life cycle from raw material extraction over production and use until the end of its life.

The Nike maker app, the Higg index and the Modint Ecotool are great tools to compare different fibre types or production processes to each other.

However, these assessment tools can only be used to get a broader insight. The specific fabric you chose may have a very different impact than suggested in the tools. The assessment tools make use of available data. At another location the impact could be way higher or also way lower than being suggested. This is why double checking is always recommended when aiming on a sustainable production.

How we make sustainable fabrics at Enschede Textielstad

We at Enschede Textielstad weave durable fabrics from natural and recycled material.

When using recycled material, the environmental impact of a fabric is reduced.

The growth of cotton for example, takes up huge amounts of water, occupies lots of land, causes emissions and uses chemicals and pesticides. The cotton growth apparently takes about 2,6% of the global water! When using a recycled content of fibres in our yarn, we can save some of this water.

The great thing is, we don’t even have to bleach or dye our fabrics! We obtain the colours of our fabrics by the recycled fibre content, that we use in our fabrics.

By having all of our suppliers nearby, we also reduce greenhouse gas emission when transporting in between shorter distances. If you live in the Netherlands, we even deliver our products by bike!

Hopefully, we could help you with the provided information. If you have any more questions about the production of sustainable fabrics, you’re mostly welcome to get in touch with us!

But for now, the following checklist should help you during your next fabric shopping.

Your checklist for buying sustainable fabrics

• Was the fabric produced locally?

• Does it contain recycled content?

• Does it contain organic content?

• Is it certified?

• Did you check one of the assessment tools? For example, the Nike MAKING App

• Do the properties of the fibres fit to what you were planning to do with the fabric?

• Was it bleached? Hopefully not…

• Printed or dyed? Printing fabrics instead of dyeing them saves lots of water