How do you recognize different fabric compositions in your textile product?

Each fabric has certain properties and characteristics. Similarly, different materials may have been incorporated into one product to enhance each other or for economic reasons. But how do you recognize these different fabrics that have been incorporated into your garment or other textile product?

A convenient and simple method to find out the raw materials of your textile product is by practising a burn test. In this way you can distinguish between plant fibers (e.g. cotton, linen), animal fibers (e.g. wool, mohair) and synthetic fibers (e.g. polyester, acrylic).

All you need for this experiment is a lighter, tweezers, and several yarns of the textile product you want to examine. (Note: it is important that you grab the yarns with tweezers, because the yarns can burn quickly.) To find out what raw materials your textile product is made up of, in the burning test, pay attention to the melting of the fiber, how the fiber

burns, what kind of smell escapes, whether the material extinguishes, what the ash residue looks like, and what the yarn end feels like afterwards.

The text continues below the images

-

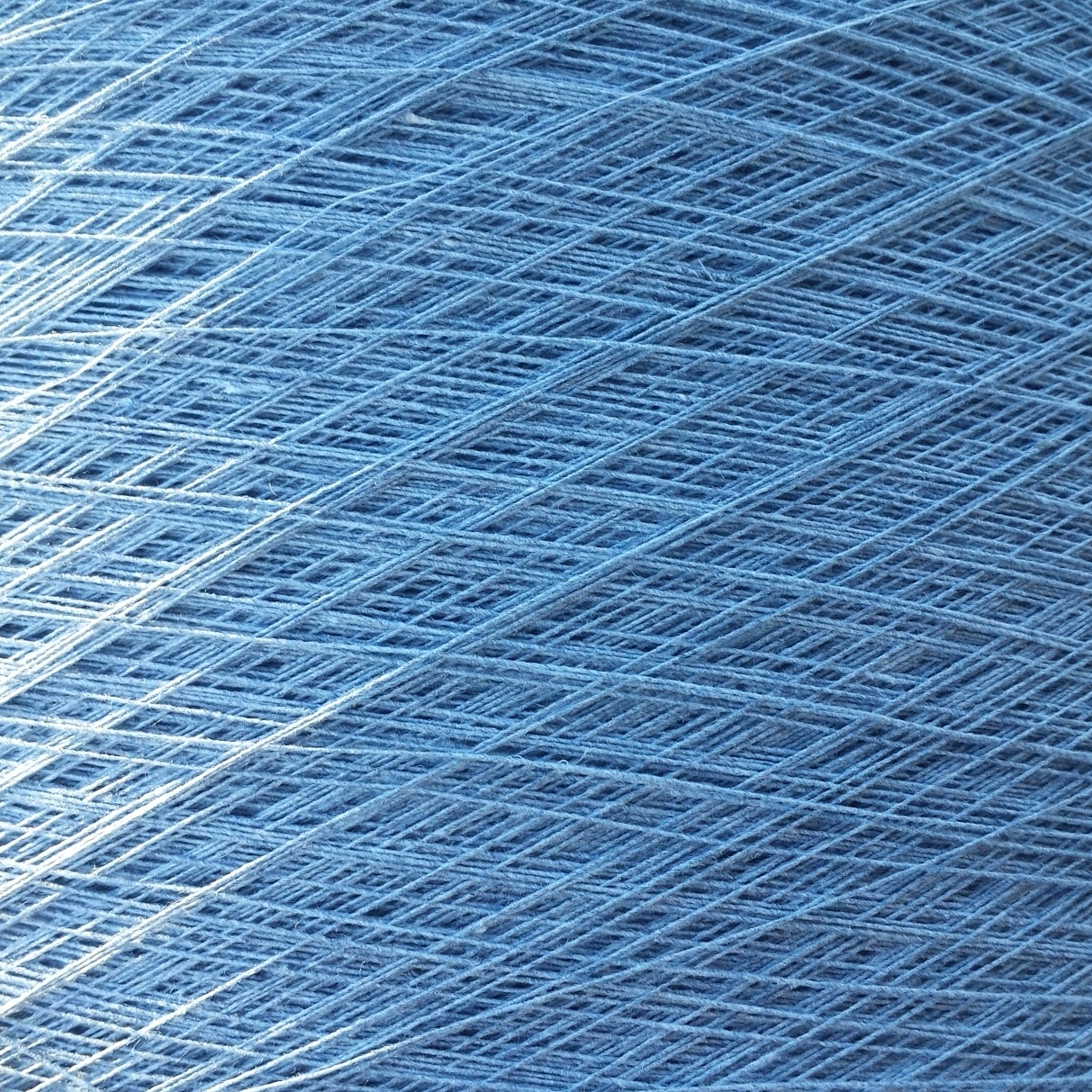

Denim Chambray

€23,00 incl. VAT (€19,01 excl. VAT) -

Panama dark blue

€24,00 incl. VAT (€19,83 excl. VAT) -

Cross twill dark blue

€26,40 incl. VAT (€21,82 excl. VAT) -

Chambray Nero

€23,00 incl. VAT (€19,01 excl. VAT) -

Panama Royal

€32,00 incl. VAT (€26,45 excl. VAT) -

Sale!

Ziggy Azulon OSC | 1,4m coupon

€130,00 incl. VAT (€107,44 excl. VAT)

Plant fibers

- Before burning: The yarn does not melt as it approaches the flame;

- During burning: The yarn burns up quickly, with the smoke giving off a light gray color and the yarn smells like burning paper;

- After burning: The yarn continues to glow for a while and the yarn end is soft.

Animal fibers

- Before burning: The yarn does not melt as it approaches the flame;

- During burning: The yarn burns up more slowly than a plant fiber, with the smoke giving off a light gray color and the yarn smells similar as burning hair;

- After burning: The yarn extinguishes on its own after removing the flame, in this process a lot of ash is produced in the form of a black ball and the yarn end is soft afterwards.

Synthetic fibers

- Before burning: The yarn melts as it approaches the flame;

- During burning: Polyester and polyacrylic burn very quickly when the yarn is lit and polyamide burns less quickly, a sooty flame can be seen in this process;

- After burning: The yarns burn through after removing the flame, the ash coming off the yarn is spherical and hard and cannot pulverize. The yarn end is hard with the exception of polyamide.

If the product is a blend of multiple fibers, then the fire behavior can be assigned to multiple groups. For example, a blend of viscose and polyester will show the burning behaviour of both a plant and a synthetic fiber.

Ultimately, this test will quickly show you which fiber group your textile product belongs to.For specific fibres in a category a microscopic research and vapour test can be carried out in a lab after the fire test, but this fire test will certainly help you a lot!